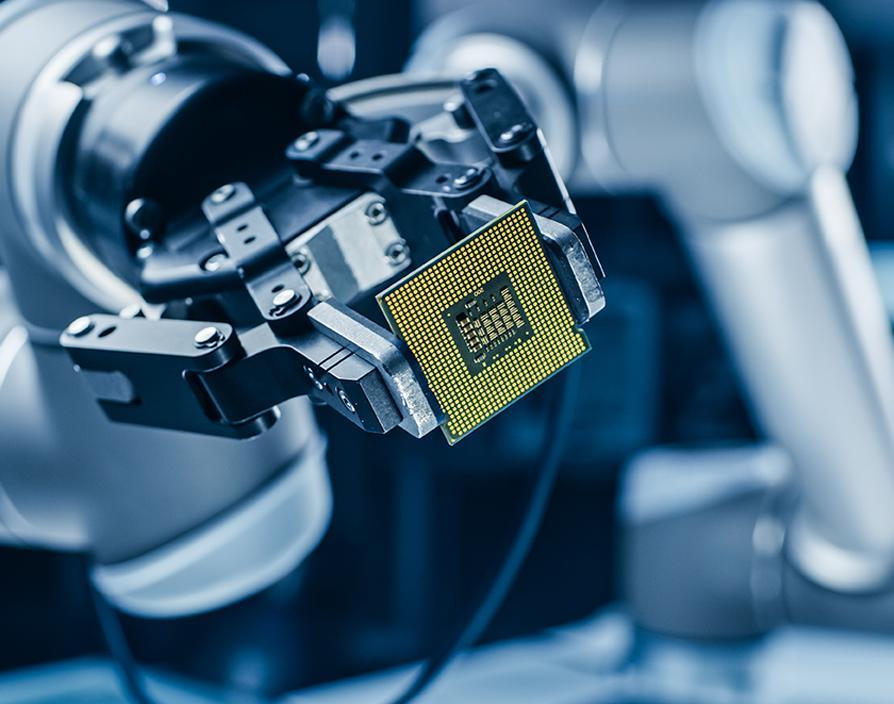

Why is the UK’s manufacturing sector not investing more in robotics when the rest of the world is rapidly embracing it?

The UK currently sits at 24th in the world robot density rankings, making it the only G7 country to fall outside the top 20. Indeed, the number of new robot installations is down 7% year-on-year, despite strong recognition shown by other countries that robotics is making a massive contribution to manufacturing efficiency and productivity – especially considering global skills shortages.

The long-term implications for UK manufacturing are worrying – unless the industry can come together to ease the adoption of automation.

Addressing financial unease

Given the widespread disruption over the past few years, the hesitancy to invest in automation throughout the manufacturing sector is understandable. Manufacturing companies have prioritised cost reduction, and margins remain so low that it can be difficult to justify significant capital investment. Furthermore, the strain on company resources extends to every level, including senior staff who are left with little time for lengthy product assessments or intricate contractual negotiations. Many businesses have also been affected by poor automation experiences in the past that leave decision-makers unwilling to try again.

These attitudes and experiences need to change. One thing they highlight is the importance of having the right partner and advice from the outset to ensure optimal outcomes. However, the automation industry must also encourage manufacturers to explore automation and robotics by making investment easier and more accessible. For example, with models such as Robotics as a Service (RaaS), where companies can rent Autonomous Vehicles (AVs), or flexible contracts that help manufacturers manage rise and fall in demand. Finally, shorter contracts could give companies the confidence to try robots without exposure to business risk.

Raising awareness

Right now, there is a lack of UK-developed robots and it is fair to assume that this will have contributed to slower uptake of the technology. If we look at countries like Poland in comparison, homegrown robotic development is certainly accelerating the understanding of, and skills in, the technology, contributing to higher adoption.

Consequently, many UK businesses are yet to experience how easily robotics can be introduced alongside the workforce. There is still a perception that Autonomous Vehicles, for example, must be purchased in a fleet, and their purpose is to replace warehouse staff. Or that robotics within manufacturing exclusively pertains to the precision used in expensive and highly efficient automotive plants.

In reality, it takes only one or two robots to add efficiency for a manufacturing SME, especially if they can redeploy staff currently undertaking repetitive, more straightforward tasks, such as transporting or packing goods, into more fulfilling work. And with a flexible contract arrangement, companies can add or remove robots in line with demand – even keeping them on site until needed, and only paying when the AV is in use.

Demonstrating benefits

As business confidence improves, manufacturing organisations need to stay on top of opportunities for change. But that will only happen if automation authorities do more to 1. show manufacturers that innovation and robotics can deliver tangible results, and 2. make investment far simpler and low risk.

Establishing a strong relationship between an SME and an automation provider requires time and effort – and the onus needs to be on the provider to go the extra mile. One way to showcase the simplicity of introducing robotics into the existing workforce is by taking an Autonomous Vehicle to a manufacturer and letting it operate alongside employees. Assisting companies through the adoption and integration process is vital to building confidence in automation.

Only by dedicating the time to help UK manufacturers invest in automation and robotics will the automation community achieve the goal of reinvigorating UK manufacturing.

Share via: